We have over 100 years in the gas detection industry. We were the first to develop poison resistant pellistor sensors for use in flammable gas detectors and the first to commercialise IR detection. Whether it is a small boiler room, school chemistry laboratory to large complex petrochemical plants; IGD have the flammable gas detector solution. We also have a free online training course “Flammable Gas Detection Basics Course“, which will help you understand Flammable gases, UK legislation, and detector technologies and which to choose: Introduction to Flammable Gas Detection Basics.

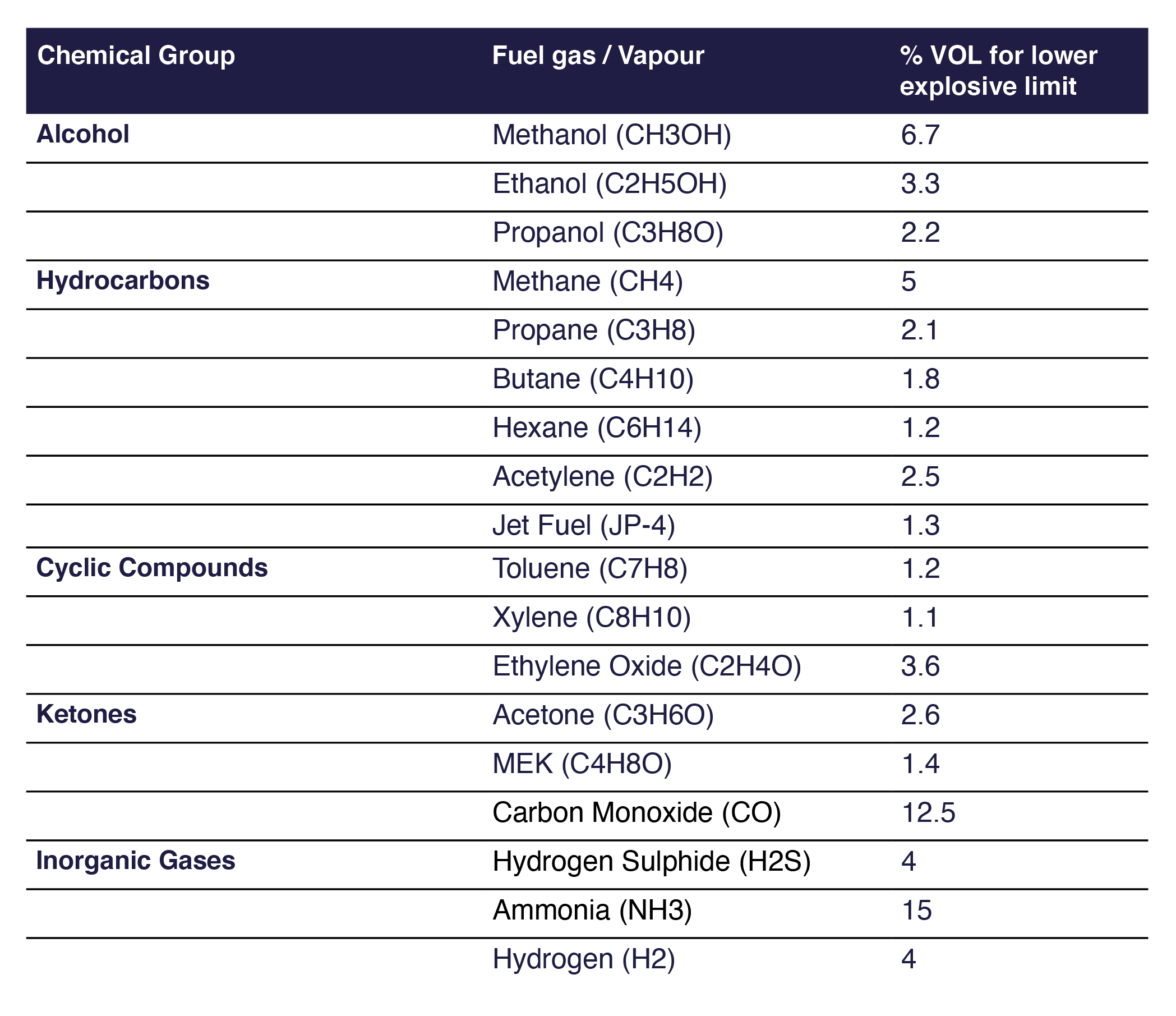

Many gases and vapours when mixed in the correct proportion with an oxidant, normally air, will ignite. If the mixture is too weak or lean when there is too much oxygen and not enough fuel gas or vapour then the mixture cannot ignite. Similarly if there is too much gas or vapour the mixture will be too ‘rich’ and so also not capable of ignition. So for a gas or vapour to ignite there must be three things present. Fuel and Oxygen in the right proportions and something (heat or energy) to ignite the mixture. This is usually represented by the fire triangle.